Leave Your Message

-

Phone

-

Email

-

Whatsapp

In the ever-evolving landscape of packaging solutions, the choice of materials plays a pivotal role in ensuring product safety and efficiency. Among these materials, Hot Melt Packing Tape has emerged as a leading option, renowned for its strong adhesive properties and versatility in various applications. According to a recent industry report by Smith & Associates, the market for Hot Melt Packing Tape is expected to grow at a CAGR of 5.2% from 2023 to 2028, driven by increasing demand across e-commerce and logistics sectors. This growth underscores the importance of selecting the right tape to meet specific packing needs.

Expert opinions further reinforce the significance of this choice. Dr. Emily Carter, a packaging industry specialist, emphasizes, "The effectiveness of Hot Melt Packing Tape lies not only in its ability to bond securely but also in its adaptability to different environmental conditions." This assertion highlights the necessity for consumers and businesses alike to understand their requirements fully before making a selection. Given the diverse applications of Hot Melt Packing Tape, from heavy-duty shipping to delicate packaging, informed decision-making is crucial in optimizing performance and ensuring the integrity of products during transit.

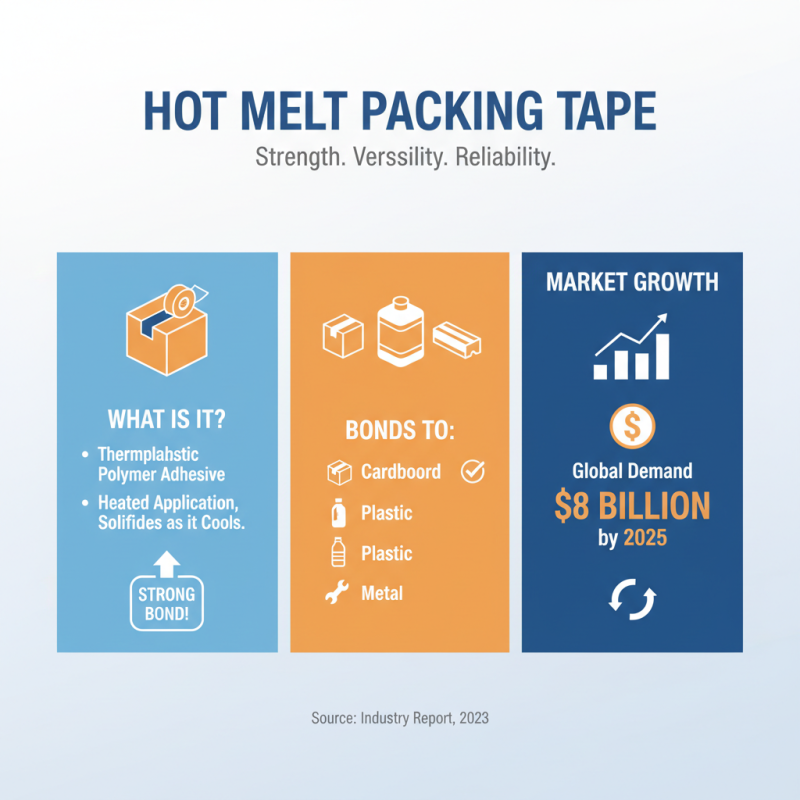

Hot melt packing tape is a widely used adhesive solution in various industries, known for its strength, versatility, and reliability. Composed primarily of a thermoplastic polymer, hot melt tape is created by applying a heated adhesive that solidifies as it cools. This type of tape is particularly valued for its excellent bonding properties to a wide range of surfaces, including cardboard, plastic, and metal. According to a recent industry report, the global demand for hot melt adhesives is projected to reach $8 billion by 2025, highlighting the growing preference for these efficient bonding solutions.

When selecting hot melt packing tape, consider its features such as adhesion strength, thickness, and temperature resistance. Thicker tapes typically offer better puncture and tear resistance, which is crucial for heavy-duty packaging applications. Additionally, temperature range specifications indicate how well the tape will perform in various environmental conditions. A study has shown that up to 30% of packaging failures can be traced back to inadequate adhesive selection, underscoring the importance of choosing the right tape for your needs.

Tips: Always test a small section of the tape on your packaging material to ensure compatibility and adhesion strength before full application. Furthermore, consider the storage conditions of the tape; excessive heat or humidity can affect its performance. Remember that a reliable hot melt packing tape can enhance your shipping efficiency and ensure your products reach their destination securely.

When it comes to selecting the best hot melt packing tape for your specific needs, evaluating adhesive strength is essential. The adhesive strength determines how well the tape will stick to various surfaces and how reliably it holds items together during shipping or storage. To assess adhesive strength, consider conducting a simple peel test: cut a piece of tape and apply it to the surface you intend to use, then peel it off at a 90-degree angle. Measure the force required to remove the tape; greater resistance usually indicates stronger adhesion.

Tips for determining your adhesive requirements include examining the surfaces that require taping. Different materials—such as cardboard, plastic, or metal—often have varied adhesion qualities. Additionally, consider environmental factors such as temperature and humidity, as these can influence the effectiveness of the tape's adhesive. For example, if you are working in a colder environment, look for tapes specifically designed to maintain their stickiness at lower temperatures. This attention to detail will help you choose a tape that performs reliably and meets your packing needs.

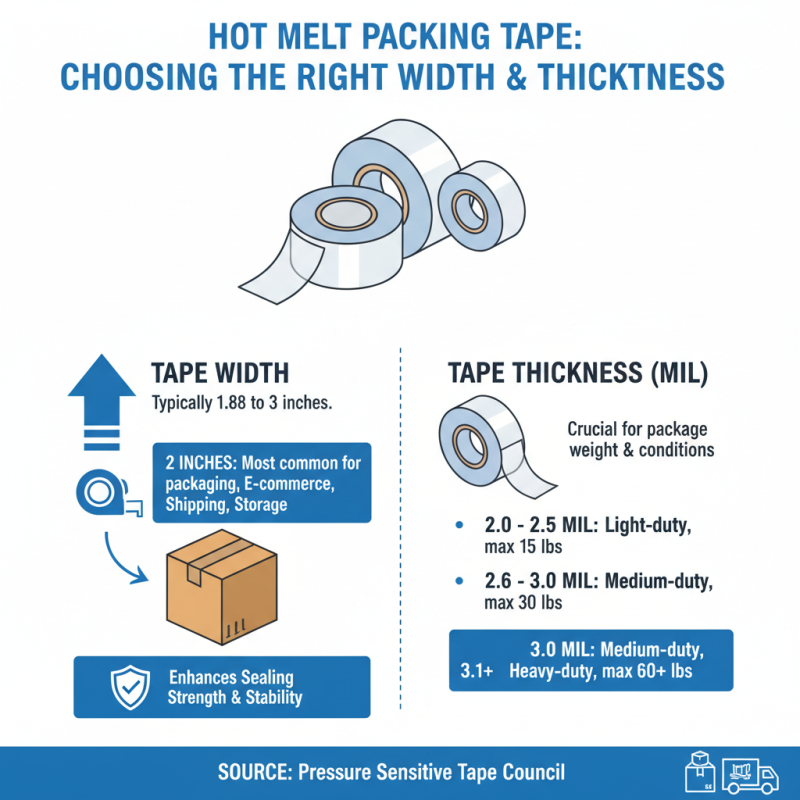

When selecting the best hot melt packing tape for your needs, the width and thickness of the tape are crucial factors to consider. Research indicates that the width of packing tape typically ranges from 1.88 to 3 inches, with the most common choice being 2 inches for general packaging. A tape width of 2 inches offers a balance between coverage and ease of use, making it ideal for securing boxes in e-commerce, shipping, and storage applications. According to industry reports, such as those from the Pressure Sensitive Tape Council, using the correct width can significantly enhance sealing strength and improve package stability during transit.

In terms of thickness, hot melt packing tapes are available in various mil thicknesses, generally from 1.5 to 3 mils. The appropriate thickness directly affects the tape's tensile strength and durability. A thicker tape (around 3 mils) is often recommended for heavy-duty applications, such as shipping larger items or storing products for longer periods. An industry study reveals that using a tape with a thickness of 2.5 mils or greater can reduce the risk of breakage during shipping and handling by up to 30%. Thus, understanding the specific requirements of your packaging needs allows you to choose the optimal width and thickness, ensuring the integrity of your shipments and the efficiency of your packing process.

When selecting hot melt packing tape, it’s essential to compare different brands and types to find the best fit for your specific needs. Hot melt tape is favored for its strong adhesive properties, making it ideal for sealing boxes and packages securely.

When evaluating brands, consider factors such as adhesive strength, thickness, and ease of application. Some manufacturers provide tape designed for heavy-duty use, while others may offer options more suited for lighter applications.

Different types of hot melt packing tape also serve various purposes. For instance, there are tapes specifically designed for cold environments, which maintain adhesion even in low temperatures, and others that are transparent for a clean presentation. Additionally, some tapes feature a reinforced backing for added durability during shipping.

Understanding the characteristics and intended use of each type will help you make an informed choice that aligns with your packing needs, whether it’s for personal use or business operations.

When selecting hot melt packing tape, environmental impact is becoming an increasingly important factor for consumers and businesses alike. The packaging industry has seen a significant shift towards eco-friendly options, motivated by sustainability goals and growing consumer awareness. According to a 2022 report by the Environmental Packagers Association, over 70% of surveyed companies expressed a preference for sustainable packaging materials, leading to a rise in the availability of eco-friendly packing tapes. These tapes often use materials that are biodegradable, compostable, or derived from recycled sources, significantly reducing their environmental footprint.

Tips: When searching for eco-friendly packing tapes, consider those made from natural rubber or water-based adhesives, which tend to have lower VOC emissions and are more environmentally benign. Look out for certifications such as FSC (Forest Stewardship Council) or ISO 14001, which indicate responsible sourcing or effective environmental management systems in place.

In addition to material composition, the production processes of these tapes also matter. Many manufacturers are adopting greener practices, such as using renewable energy in their production lines and minimizing waste during manufacturing. A survey conducted by EcoPack in 2023 showed that companies utilizing sustainable practices have reported a 40% reduction in overall manufacturing waste. Thus, selecting a packing tape that aligns with eco-friendly standards not only benefits the environment but also supports a growing trend towards responsible business practices.

This chart compares the environmental impact of different types of hot melt packing tapes based on biodegradability, recyclability, and raw material sourcing.