Leave Your Message

-

Phone

-

Email

-

Whatsapp

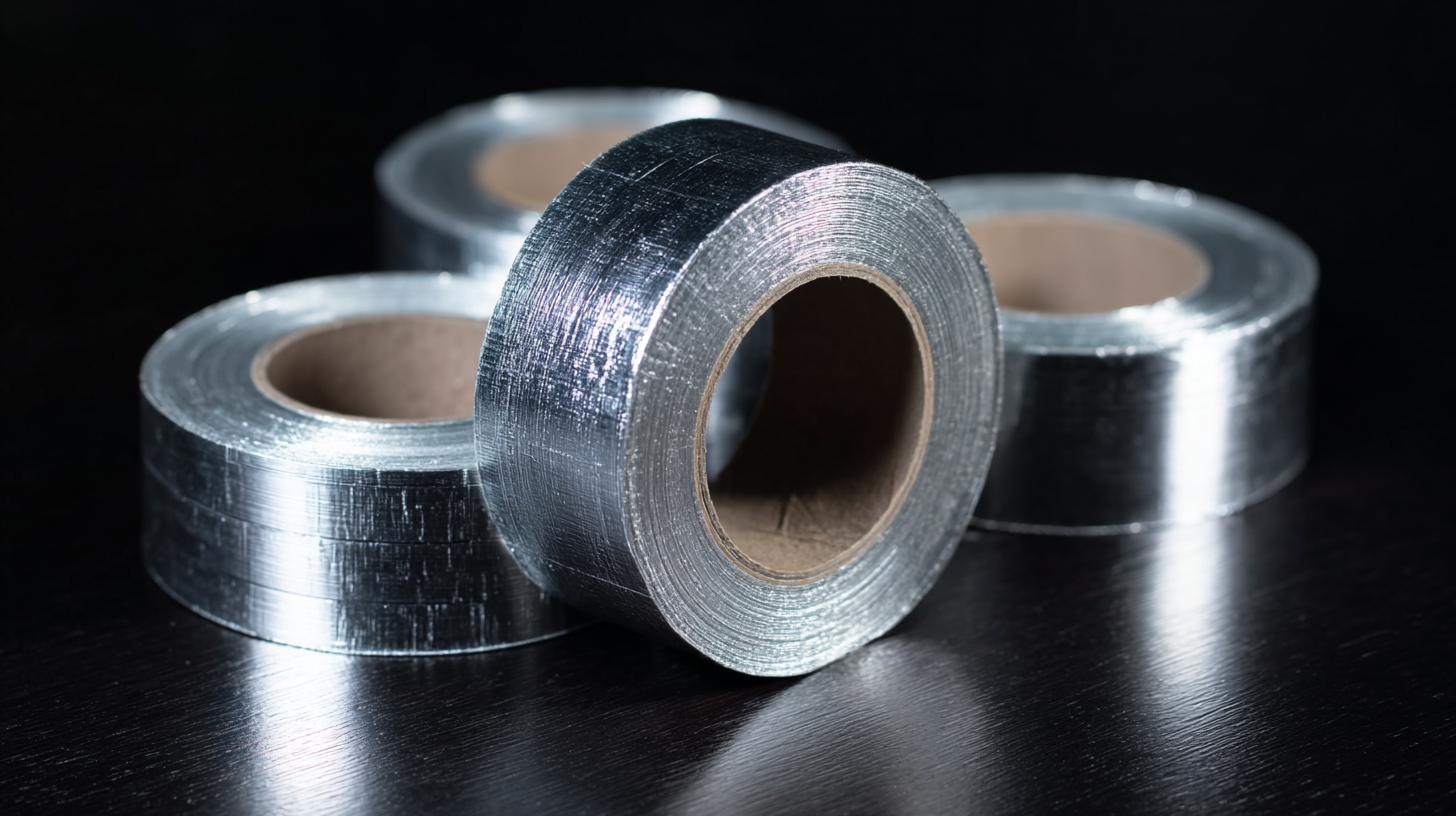

Silver Duct Tape, often referred to as the ultimate repair solution, possesses a unique combination of durability and versatility that has made it a staple in households and industries alike. Its remarkable tensile strength plays a crucial role in its effectiveness, enabling it to withstand significant stress and pressure without tearing or losing adhesion. This has led to a multitude of applications, from simple home repairs to complex industrial tasks. Understanding the properties and advantages of Silver Duct Tape can empower users to harness its full potential in various repair situations. In this article, we will explore the significance of tensile strength in Silver Duct Tape and how it enhances its functionality, making it one of the best options available for anyone seeking reliable and lasting repair solutions.

Silver duct tape, often recognized by its distinctive metallic sheen, is a versatile adhesive tape widely used across various industries for repairs and assembly. Its unique properties stem from a combination of a strong adhesive, a durable backing, and the ability to conform to irregular surfaces. According to a report by the Adhesive and Sealant Council, the market for tapes, including duct tape, is projected to grow significantly, driven by increased demand in construction and automotive sectors. This growth underscores its importance as a critical tool in repair solutions.

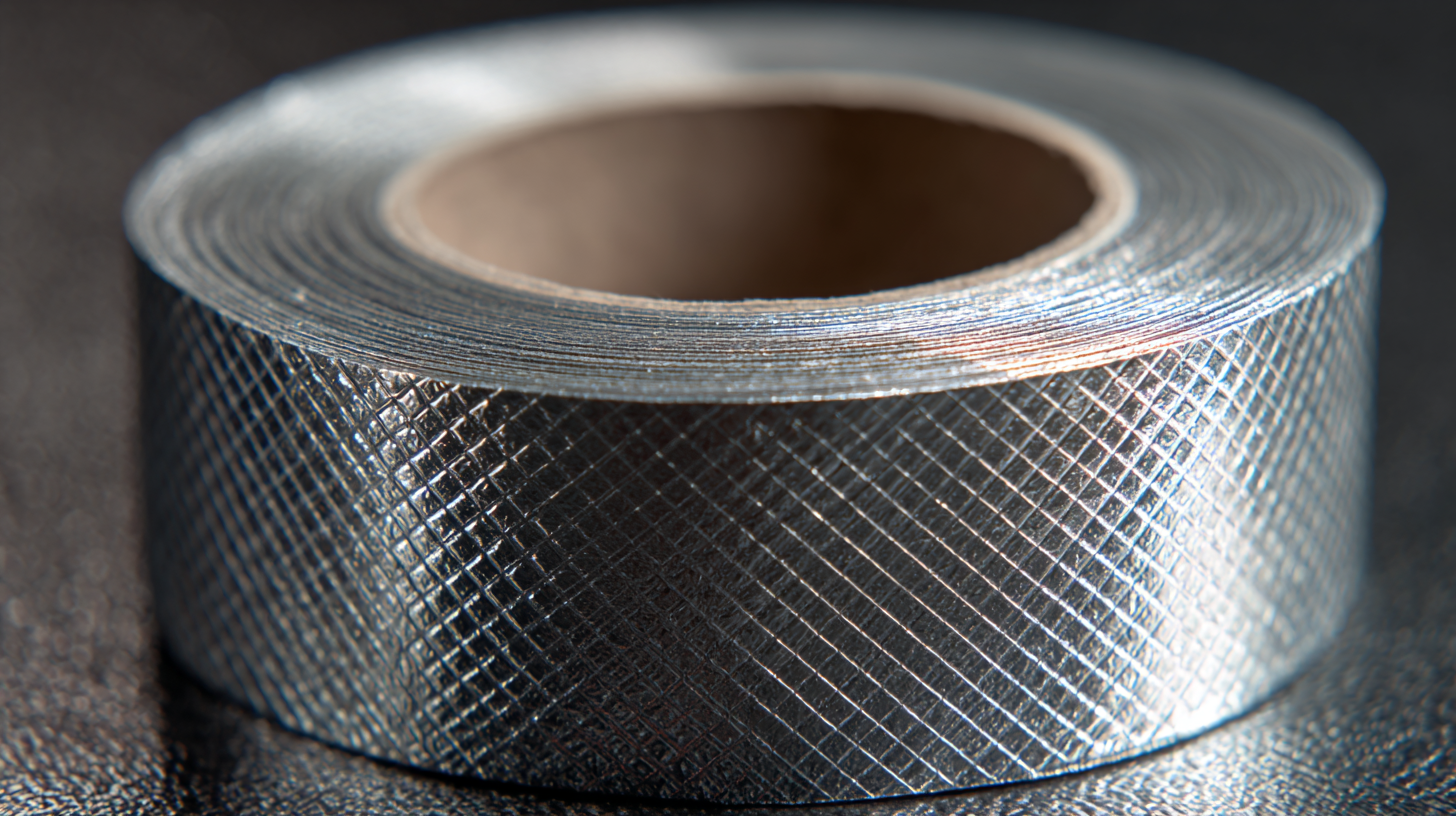

One of the standout features of silver duct tape is its impressive Tensile Strength, which typically ranges between 17 to 80 pounds per inch, depending on the brand and specifications. This high tensile strength allows it to withstand substantial stress and strain, making it ideal for everything from sealing ducts in HVAC systems to emergency repairs on automotive and industrial equipment. Furthermore, it can endure varying temperatures and harsh environmental conditions, ensuring reliability in both indoor and outdoor applications. With its strong bond and flexibility, silver duct tape remains a go-to solution for quick and effective repairs in numerous scenarios.

Tensile strength is a critical parameter in repair solutions, influencing the durability and effectiveness of various materials used in construction and medical applications. For instance, in the context of bonded concrete overlays, the shear bond between existing concrete and high-strength fiber-reinforced overlays is essential. Studies have demonstrated that increased substrate strength and appropriate interface roughness significantly enhance the overall performance of these repairs, showcasing the importance of tensile strength in ensuring structural integrity (source: recent studies on concrete reinforcement).

In the biomedical field, tensile strength also plays a vital role in the effectiveness of materials used for repairs. For example, polysaccharide-protein-based scaffolds exhibit promising mechanical properties for cartilage repair, essential for ensuring that these materials can withstand physiological loads during the healing process. Additionally, the mechanical properties of materials used in hernia repair have been extensively reviewed, highlighting the need for high tensile strength to prevent complications and ensure successful recovery. Such insights underline how understanding and optimizing tensile strength can lead to more reliable and effective repair solutions across various industries.

Silver duct tape is more than just a handy item in your toolbox; it has become a staple in various everyday repair solutions. This versatile adhesive tape is renowned for its exceptional tensile strength, which typically ranges from 30 to 60 pounds per inch of width, making it ideal for a myriad of applications. From fixing a leaky toilet to mending a favorite childhood teddy bear, its durability and flexibility allow users to tackle unexpected challenges efficiently. In fact, many households consider it an essential tool for quick fixes in the absence of a professional handyman.

Moreover, the innovation surrounding duct tape continues to evolve, as evidenced by its use in creative and practical applications. For instance, caregivers of disabled individuals often turn to duct tape to craft low-cost assistive devices, showcasing the tape's adaptability beyond traditional uses. Notably, NASA has utilized duct tape for tasks ranging from securing loose equipment on space missions to repairing lunar rovers, underscoring its importance in critical situations. Whether for casual home improvement tasks or emergency repairs, silver duct tape remains a dynamic solution for everyday needs, solidifying its reputation as a reliable partner in both mundane and extraordinary circumstances.

Silver duct tape has long been a staple in the world of repairs and DIY projects, but how does it measure up against other adhesive tapes? While traditional packaging tape may offer convenience for light-duty tasks, silver duct tape outshines it in both tensile strength and versatility. According to a report by the Adhesive Tape Manufacturers Association, silver duct tape typically boasts a tensile strength ranging from 20 to 30 pounds per inch, making it ideal for heavy-duty applications. In contrast, standard masking or packaging tapes usually fall short, with tensile strengths barely exceeding 10 pounds per inch.

Silver duct tape has long been a staple in the world of repairs and DIY projects, but how does it measure up against other adhesive tapes? While traditional packaging tape may offer convenience for light-duty tasks, silver duct tape outshines it in both tensile strength and versatility. According to a report by the Adhesive Tape Manufacturers Association, silver duct tape typically boasts a tensile strength ranging from 20 to 30 pounds per inch, making it ideal for heavy-duty applications. In contrast, standard masking or packaging tapes usually fall short, with tensile strengths barely exceeding 10 pounds per inch.

Moreover, when compared to specialty tapes like gaffers tape or double-sided tape, silver duct tape often offers superior adhesion and durability, especially when applied to rough or uneven surfaces. A study conducted by an industry analyst at Market Research Future revealed that, among various adhesive tapes, duct tape held a market share of over 40% just for its multifunctionality. The ability to withstand moisture and temperature fluctuations enhances its appeal, particularly in outdoor or industrial environments, where other types might fail. This durability and strength make silver duct tape an invaluable tool in a wide range of repair solutions.

When selecting the right silver duct tape for your needs, it’s essential to consider several factors that contribute to its effectiveness in various repair solutions. One of the most critical aspects is its tensile strength, which determines how much stress the tape can withstand before breaking. Higher tensile strength means better durability and reliability for heavier-duty tasks, making it a preferred choice for both home repairs and larger projects.

Another vital consideration is the adhesive quality, which affects how well the tape bonds to different surfaces. Some duct tapes are designed for specific materials, whether metal, wood, or plastic, so assessing the surface you will be working with is crucial. Additionally, weather resistance may be significant if you plan to use the tape outdoors. Opt for a tape that offers good performance against moisture and temperature variations, ensuring that your repairs last longer, even in challenging environments. Understanding these factors will help you make an informed decision and choose the best silver duct tape for your repair needs.

| Attribute | Description | Typical Value |

|---|---|---|

| Material | Polyethylene film backing with a strong adhesive | N/A |

| Tensile Strength | The maximum amount of tensile (pull) stress that can be applied | 15-25 lbs/in (depending on the product) |

| Adhesive Strength | How well the tape adheres to surfaces | High (initial tack) |

| Weather Resistance | Ability to withstand moisture, UV light, and temperature changes | Good |

| Typical Applications | Repairing, sealing, and waterproofing tasks. | Varies (household, industrial, crafts) |