Leave Your Message

-

Phone

-

Email

-

Whatsapp

Adhesives play a critical role in various industries, with the global adhesive market projected to reach $62 billion by 2025, according to a report by Grand View Research. Among these adhesives, Cello Tape, a popular form of pressure-sensitive tape, is widely used in everyday applications ranging from simple household tasks to complex industrial processes. Understanding the science behind Cello Tape can illuminate how its unique properties, such as tackiness and adhesion, make it an indispensable tool in our daily lives. The efficiency of Cello Tape, combined with its ease of use, exemplifies the advancements in adhesive technology, which not only facilitates seamless packaging and repairs but also enhances productivity across multiple sectors. As we delve into the mechanics of how Cello Tape functions, we uncover the intricate balance of chemical formulation and application techniques that make it a staple in both domestic and professional environments.

The chemistry of adhesive bonding is a fascinating realm that combines materials science with molecular interactions to create strong and lasting bonds. At its core, adhesive bonding occurs when two surfaces are brought into contact with an adhesive substance that facilitates the connection. These adhesives may be composed of polymers, which are long chains of molecules that can create substantial adhesion through various mechanisms such as van der Waals forces, hydrogen bonding, and even chemical reactions that lead to curing or cross-linking.

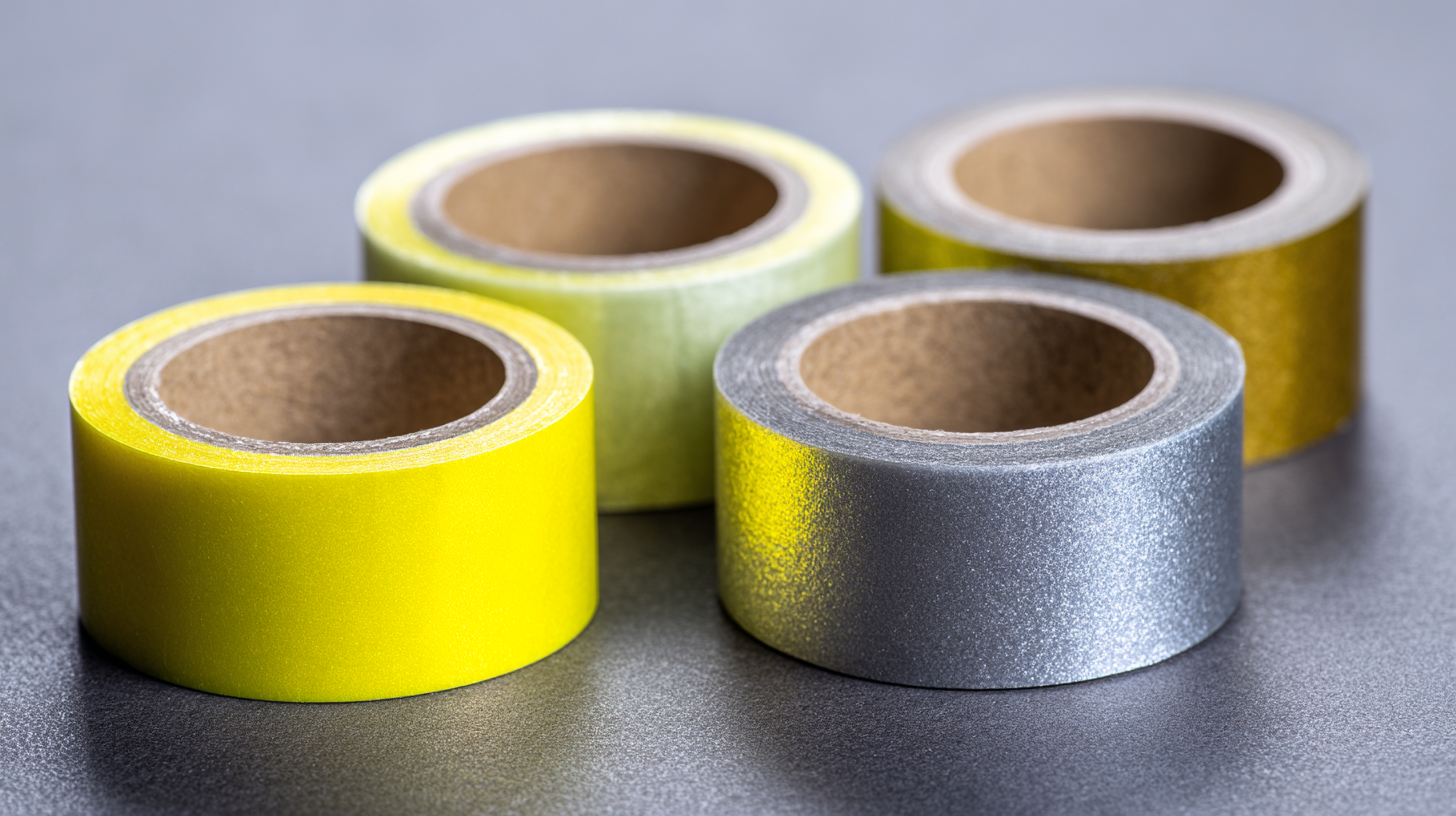

Different adhesives serve diverse applications, ranging from everyday items like cello tape to advanced engineering materials. Cello tape, for instance, employs a pressure-sensitive adhesive that becomes tacky upon contact, allowing for easy application and removal without leaving residue. This is due to its unique formulation that balances elasticity with cohesive strength. The ability of an adhesive to bond different materials, such as plastic, paper, or metal, hinges on its chemical composition and the nature of the surfaces it connects. Understanding these intricate chemical interactions not only enhances product effectiveness but also drives innovations in adhesive technology across various industries.

Adhesives come in various types, each designed to serve specific purposes based on their unique properties. The most common categories include pressure-sensitive adhesives, reactive adhesives, and hot melt adhesives. Pressure-sensitive adhesives, such as those used in tape, bond when pressure is applied, making them ideal for temporary applications like mounting posters or sealing packages. Their ease of use and removability make them popular in both household and office settings.

Reactive adhesives, on the other hand, require a chemical reaction to form a bond. These include epoxies and cyanoacrylates, which are known for their strength and durability. They are often used in construction, automotive, and aerospace applications due to their ability to withstand high stress and environmental exposure. Lastly, hot melt adhesives are thermoplastic materials that become liquid when heated and solidify upon cooling. They are commonly employed in packaging, woodworking, and crafting, providing a quick and effective bonding solution. Understanding these distinct types of adhesives helps in selecting the right product for various tasks, ensuring optimal performance and reliability.

| Type of Adhesive | Key Properties | Common Uses |

|---|---|---|

| Pressure-Sensitive Adhesives | Immediate bonding, removable, no heat required | Tape, labels, post-it notes |

| Hot Melt Adhesives | Fast setting, good temperature resistance, applied hot | Packaging, woodworking, automotive |

| Epoxy Adhesives | High strength, chemical resistance, two-part mix | Construction, metal bonding, electronics |

| Polyurethane Adhesives | Flexible, waterproof, good adhesion to various materials | Woodworking, leather, textiles |

| Silicone Adhesives | High flexibility, temperature resistant, waterproof | Sealing, assembly in electronics, medical devices |

Pressure and temperature play critical roles in the performance of adhesives, particularly in common applications like cello tape. Adhesive bonds are formed when pressure is applied, allowing the adhesive to flow into the micro-scale surface roughness of the materials being joined. According to a report by the Adhesives and Sealants Industry (ASI), optimal pressure application can enhance the bond strength by nearly 50%. This underscores the importance of understanding how pressure influences adhesion, especially in high-demand environments such as packaging and construction.

Temperature also significantly affects adhesive performance. Many adhesives have specific temperature ranges within which they achieve optimal bonding. When temperatures are too low, the adhesive may not flow properly, leading to weak bonds or complete failure. Conversely, excessive heat can diminish the adhesive's cohesive strength, resulting in a loss of adhesion. A study from the American Institute for Manufacturing Technologies indicates that extreme temperature fluctuations can reduce the lifespan of adhesive bonds by up to 30%, impacting everything from everyday uses like cello tape to more critical applications in automotive and aerospace industries. Thus, monitoring both pressure and temperature is essential for maximizing adhesive effectiveness and ensuring long-lasting bonds.

Cellophane tape, commonly encountered in homes and offices, has a multitude of innovative applications that go beyond mere gift wrapping. This versatile adhesive is utilized in various fields ranging from education to craft projects, and even in specialized sectors like healthcare. For instance, researchers are exploring cellophane tape for its potential use in developing smart bandages that can monitor wound conditions and deliver medication. Such applications highlight how a simple adhesive can play a significant role in enhancing everyday functionality and improving health outcomes.

Additionally, the rise of tech-driven lifestyles presents unique opportunities for cellophane tape applications. As people become more engaged in DIY projects and personalized crafting, the demand for reliable adhesives has surged. Businesses are capitalizing on this trend by developing specialty tapes designed for different materials, such as fabric or electronics. Reports indicate that the adhesive tapes market is anticipated to reach over $57 billion globally by 2025, driven by innovation and increased consumer engagement.

**Tips:** When working with cellophane tape, consider its thickness and adhesive strength for optimal use in your projects. For crafting, clear tape is great for seamless finishes, while colored varieties can add a decorative touch. Always ensure the surface is clean and dry for the best adhesion results.

Future trends in adhesive technology are paving the way for significant advancements across various industries. As we move into an era marked by the integration of 5G, artificial intelligence, and the Internet of Things, traditional adhesive applications must evolve to meet the growing demands for efficiency and performance. Temporary bonding techniques, particularly in wafer-level packaging, are gaining attention as they offer innovative solutions to enhance semiconductor functionality without solely relying on reducing manufacturing sizes.

Simultaneously, the drive towards sustainability is pushing the development of eco-friendly adhesives and packaging materials. This transformation is propelled by rising environmental consciousness and the pursuit of sustainable development goals, prompting an increasing number of countries and organizations to prioritize the use of green materials. As these trends intertwine, future adhesive technologies are expected to focus not only on performance but also on environmental impact, leading to the creation of high-performance films and bonding agents that align with modern ecological standards.