0102030405

Premium Grade PVC Electrical tape Insulation tape

Features

Insulating Performance

Electrical tape is designed to insulate electrical wires, preventing current from transmitting to other components or people, thus avoiding electric shocks or fire hazards.

Versatility

It offers electrical insulation, flame resistance, weatherability, acid/alkali resistance, and mechanical protection, suitable for insulating and protecting various wires and cables.

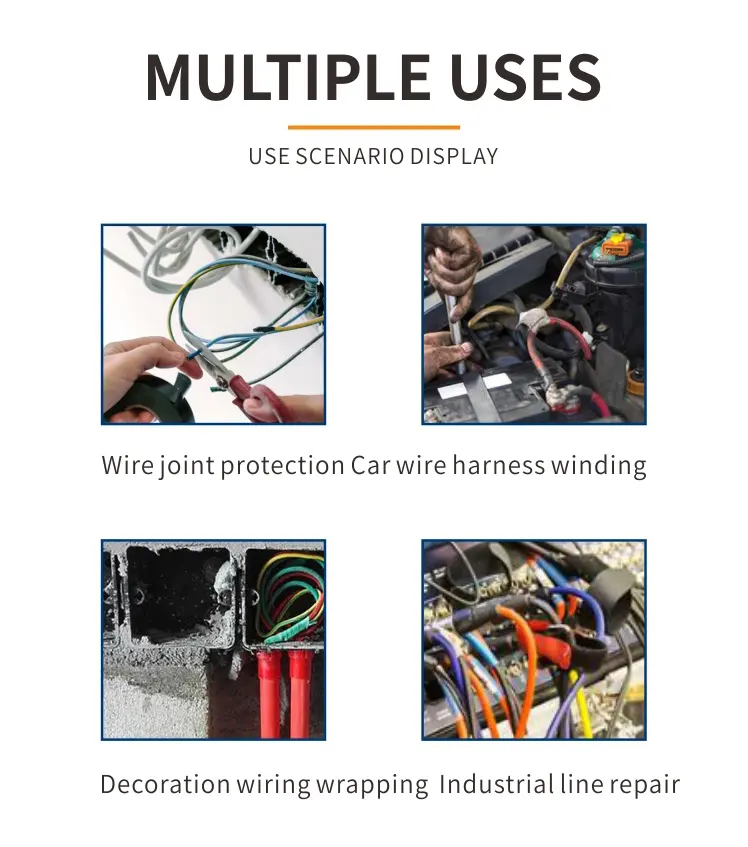

Application Scenarios

Widely used in indoor and outdoor electrical installations, repairs, and insulating wire/cable joints up to 600V. Also used for bundling wires/cables and providing phase identification.

Insulation tape is vital for electrical safety, protecting wires from moisture, heat, and accidental contact. Begin by preparing the surface—ensure wires are clean, dry, and free of debris to promote strong adhesion. Cut the tape to the required length, slightly longer than the area to be covered. Start wrapping from the base of the wire, overlapping each layer by 50% to ensure complete coverage. Apply even tension to eliminate air pockets, which could compromise insulation.

For joints or splices, wrap the area thoroughly, extending coverage beyond the exposed section. Secure the end by stretching the tape slightly and pressing firmly. Avoid stretching excessively, as this may weaken the adhesive. Finally, inspect the wrap for gaps or loose edges. Properly applied insulation tape extends equipment lifespan and prevents electrical hazards. Always prioritize safety!

For joints or splices, wrap the area thoroughly, extending coverage beyond the exposed section. Secure the end by stretching the tape slightly and pressing firmly. Avoid stretching excessively, as this may weaken the adhesive. Finally, inspect the wrap for gaps or loose edges. Properly applied insulation tape extends equipment lifespan and prevents electrical hazards. Always prioritize safety!

description2